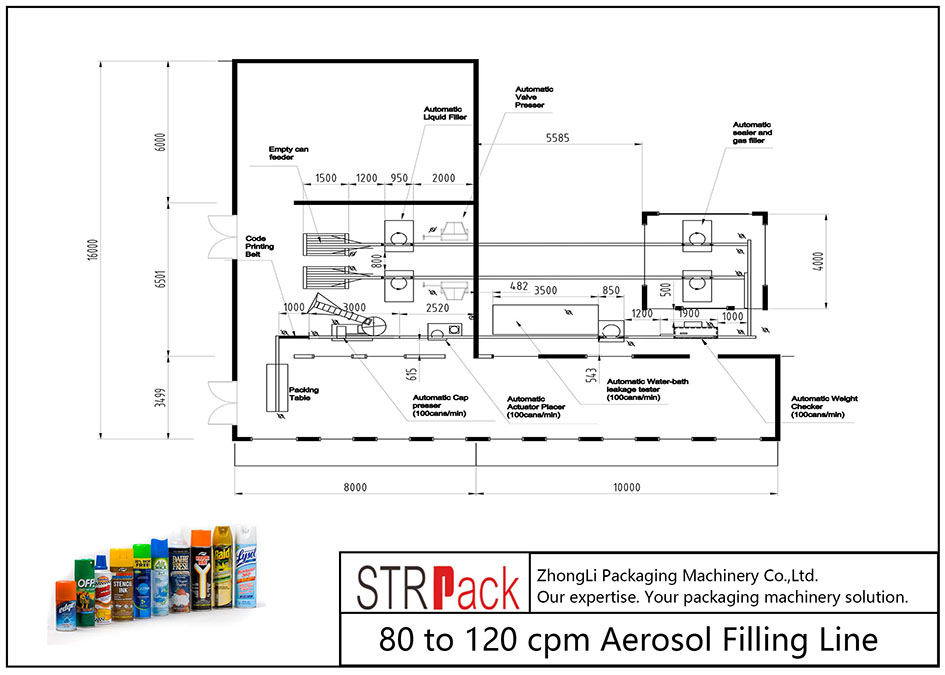

80 to 120 cpm Aerosol Filling Line

80 to 120 cpm Aerosol Filling Line

Filling Line Details

80 to 120 cpm Aerosol Filling Line adopt Y shape design layout, using 2 sets of Automatic Aerosol Filling Machine and 2 sets of Aerosol Valve Inserter for filling, valve inserting, crimping and gassing. The end parts will adopt high speed machines including Aerosol Can Check weigher,Water-bath Leakage Tester, Automatic Actuator Placer and Automatic Cap Presser, make the aerosol production line to reach the high speed at 120 cans per minute.

The production line achieve that no cans not filling, auto shut down when cans stuck, the crimping heads with automatic locking device to stabilize the sealing size. The propellant filling head is also no cans no fill, accurate, efficient and little gas consumption. Adopt Japan SMC pneumatic components .

Machines Included:

· Automatic Aerosol Filling Machine

· Automatic valve inserter

· Automatic Weight Checker

· Automatic Water-bath Leakage Tester

· Automatic Actuator Placer

· Automatic Cap Presser

Technical Specifications

| Product filling capacity | 50-750ml |

| Product filling accuracy | ≤±1% |

| Propellant filling capacity | 50-750ml |

| Propellant filling accuracy | ≤±1% |

| Valve sealing accuracy | ≤±1% |

| Production capacity | 3,600-5,400 cans/hr |

| Working pressure | 0.65-1Mpa |

| Maximum air consumption | 5m³/min |

| Applicable aerosol can diameter | 52-65mm |

| Applicable aerosol can height | 80-330mm |

| Aerosol valve requirement | 1” international standard aerosol valve |

| Power supply | 380V or per customer’s specification |